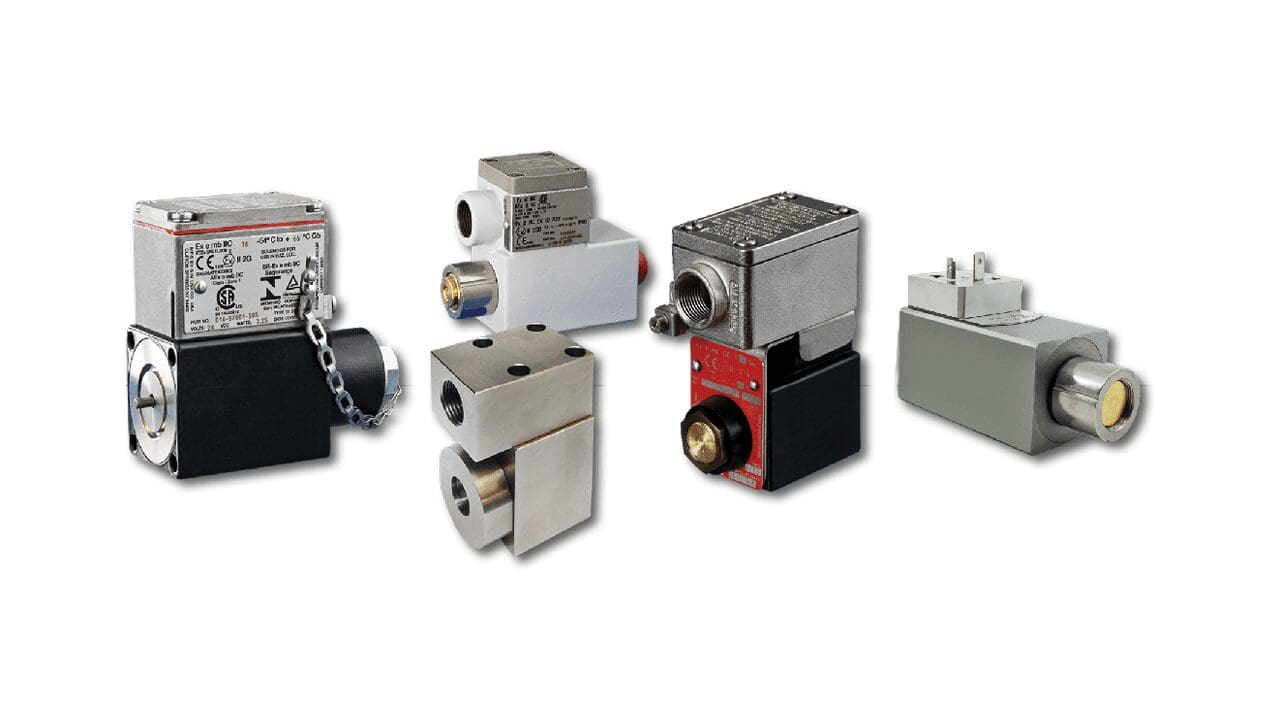

Enhanced Safety in Demanding Environments

Hazardous location solenoids are used in places where fire or explosion hazards may exist due to flammable gases, flammable liquids, combustible liquid, combustible dusts or ignitable fibers being present in the air in quantities sufficient to produce explosive or ignitable mixtures. Hazardous location solenoids are specifically designed to prevent an ignition source from coming into contact with the explosive atmosphere.

Lisk has decades of experience developing hazardous location solenoids utilizing varying methods of protection. We work collaboratively with you to make sure the optimal solenoid is designed for your hazardous location application. We use the following types of protection methods.

Flameproof

Flameproof or Explosion proof prevents any internal ignition of gas from escaping. Since flammable gases and vapors are expected inside an enclosure, the equipment must be capable of withstanding an explosion caused by sparking contacts of devices, high temperatures, or an electrical fault. The enclosure is designed so that hot gases generated during an internal explosion are cooled below the ignition temperature of the surrounding flammable atmosphere as they escape through the joints of the unit.

Intrinsically Safe

Intrinsically safe protection must have components and connectors that are incapable of producing sparks or heat under either normal or fault conditions that could cause ignition of an explosive atmosphere. Typically, voltages and currents are kept at low levels.

Increased Safety

Increased safety is type of protection applied to electrical equipment that does not produce arcs or sparks in normal service and under specified abnormal conditions, in which additional measures are applied so as to give increased security against the possibility of excessive temperatures and of the occurrence of arcs and sparks.

Encapsulation

Encapsulation is a type of protection in which the parts that can ignite an explosive atmosphere are enclosed in a resin. The resin must be sufficiently resistant to environmental influences so that the explosive atmosphere cannot be ignited by either sparking or heating, which may occur within the device. The electrical connections exiting out of solenoid needs to be protected or terminated in a safe area. Typically increased safety protection is used.

Applications

- Topside Oil Rigs

- Petroleum Refineries

- Petroleum Transport Ships

- Grain Mills

- Gas Turbines

- Power Generation

- Chemical Plants

- And More!

Rigorously Tested

Hazardous location solenoids must be tested to ensure they do not initiate an explosion, due to arcing contacts or high surface temperature of equipment. We use a variety of testing processes to ensure that these solenoids offer reliable performance.

- Flameproof solenoids are certifying agency tested.

- Intrinsically safe solenoids are thermally tested.

- Encapsulation solenoids are certifying agency tested. The testing includes 28 thermal cycling and dielectric test at elevated temperatures.